Prepping, Alodine, and Priming

I purchased alumaprep, alodine, and epoxy primer 20 years ago. All still works as it should. Who would have thought?

I wanted to get started priming this winter, so I set up a grow tent to use for a paint booth. I do a lot of woodworking and had an extra dust collector I never used that came with a panel sander. I made a filter box exhausting out the back of the tent, then out through a window. It works great! I can't smell anything when painting and could probably get by without using a respirator, but just to be safe.......

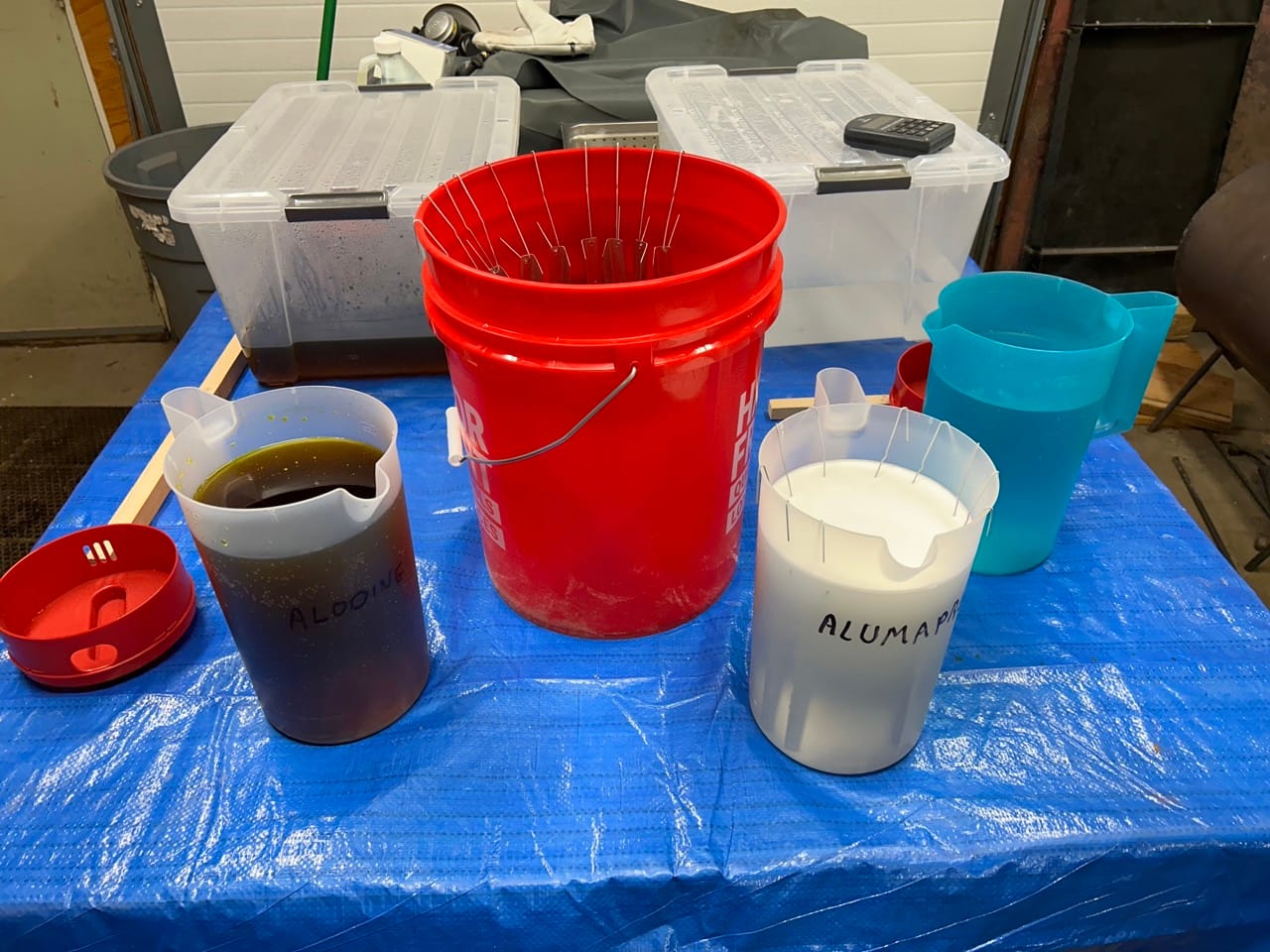

For the alumaprep and alodine, I'm using buckets and containers for the smaller parts. Maybe by the time I'm ready for the larger parts, the weather will allow doing it outside. I started out stringing a batch of angles on a wire, but the angles kept sticking to each other when wet. Now, I'm hanging parts individually on paper clips. It works considerably better to pour rinse water over parts instead of dipping in rinse water. Also, after rinsing and hanging up to dry, blow the part off with air as if you don't you will get pooling of alodine at the bottom of the part which leaves a stain that doesn't cover that well with primer. Doubt that it hurts anything, but I want everything to be just so.

Finally got through all the stiffeners and starting the nose ribs

When prepping parts, I wiped down with acetone, then scrubbed well with Dawn dish soap and water using a scotch brite pad. Using scotch brite scuffs the surface just enough to give a little bit of tooth. I cut circles out of the scotch brite pads and mounted on my buffer which made short work of scuffing in the flute locations.