Flap Hinge Mount

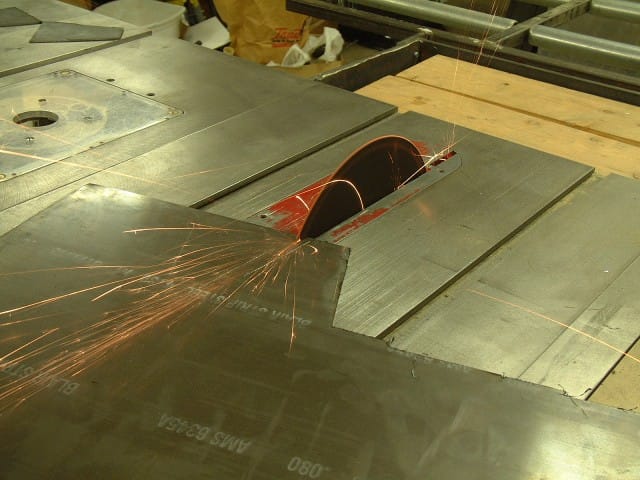

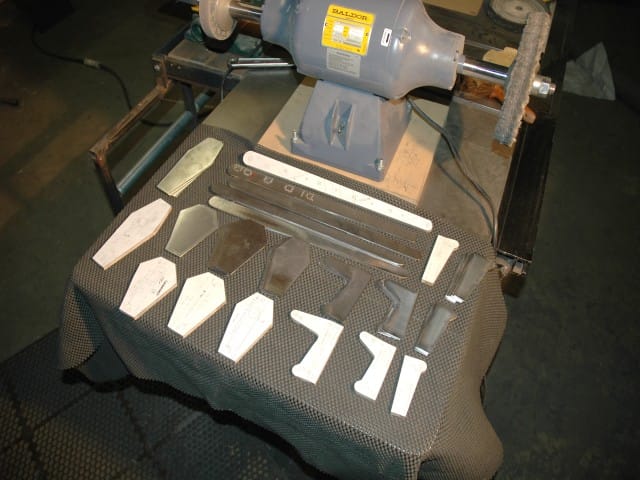

To rough cut the flap hinge mount, and support frame mount blanks, I used an abrasive blade in my table saw, then finished shaping using a grinder, sander, and buffer. Completed blanks prior to bending and drilling

To make the first bend in the mounts, I bent the blank 90 degrees over a piece of 3/4" x 3" x 7" mild steel. I had an 1/8" radius machined on the edges of the bending 'anvil' to achieve the required bending radius. To make the u shape 13/16" wide, I bent a piece of .032 aluminum around the bending anvil, then bent the second leg 90 degrees.

As others have done, I want to run the support frame tube long so I can weld around the tube on the outside of the bracket. After drilling the 3/4" holes with a hole saw, I final fit the tubing hole using a die grinder with a carbide burr. To cut the rectangular push rod hole, I drilled a 1/4" hole in each corner, then cut between the holes using an abrasive cutoff wheel in the die grinder.

To assemble the flap and aileron hinge mounts, I constructed this jig following the instructions given in the summer '95 issue of Beartraks. The flap hinge mount uses the center set of tabs, and the aileron hinge mount uses the outer set of tabs. I sanded the appropriate angle on the end of the 3/4" tubes