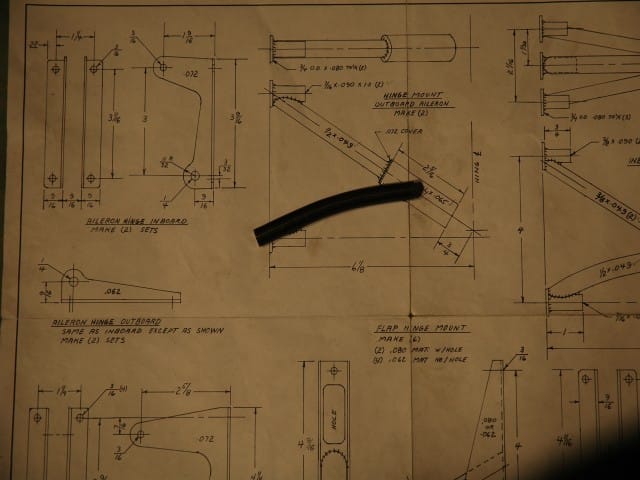

Aileron Hinge Mount

To make the washers for the aileron hinge mounts, I drilled holes in a sheet of .080 4130. I'm going to use .080 for all the washers. Then I rough cut 1" washers using a plasma cutter. I final shaped the washers to 3/4" using a belt sander as the washers were turning on a bolt in my drill press.

To prep the tubes for welding, I sanded the mill scale off using emery paper. I sand blasted the smaller tubes and the washers, then wiped down with alcohol. Tubes and washers ready for welding.

rior to welding, I had to drill the tubes to the proper size. I held the tubes and washers together with the appropriate sized bolt and nuts. A couple of welded tubes and washers

To bend the curved lower tube on the aileron hinge mounts, I shaped a piece of 1" flat steel I had to match the drawing. I used my 12" disc sander for this. I then sandwiched the tube between 1/4" MDF on my press. This kept the tube from rolling and also flexed enough to complete the pressing operation. I pressed until the outer edge of the curve on the press die came into contact with the tube. This worked very well with minimal set up.

Just like the drawing. I made the tube longer than required, because during pressing, a small kink happened where the tube was in contact with the press supports. I cut these kinks off to make the tube the correct length. Here I have one of the upper straight legs tacked on. I have started to use my mig welder for tacking instead of gas tacks. I'm using ER70S-6 .023 wire which is the same type as the gas filler rod. This leaves a small tack that I will be able to gas weld right over.